Dynamic and Nonprehensile Manipulation: Vibratory Manipulation

About

This project examines a very simple and versatile robotic manipulator with surprising capabilities: a six-degree-of-freedom (6-dof) rigid vibrating plate whose motion can be programmed. Even though this manipulator has no grasping ability, it can be used to create programmable vector fields describing how parts will slide on the surface under the influence of friction. These vector fields can be used to manipulate a single part (e.g., to orient or position it), or to manipulate multiple parts along independent trajectories (e.g., to assemble or sort them).

For example, some plate motions cause all parts to move directly to a specific point on the plate surface; other plate motions cause parts to align themselves along a desired axis; yet others sort parts based on their friction coefficients. By studying the dynamics of the plate-part system, we seek to understand the full set of vector fields that can be generated with a 6-dof plate. By exploiting these fields, we can perform manipulation tasks in which parts are moved from one set of configurations to another one.

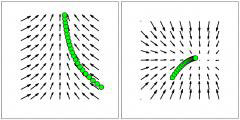

The manipulator works because for any small-amplitude periodic plate motion, point parts (or rigid parts in three-point contact with the plate) move as if they are immersed in a configuration-dependent velocity field. Specifically, there is a unique mapping from every small-amplitude periodic plate motion to a corresponding velocity field, which we call an asymptotic velocity field. To a very good approximation, parts can be modeled as "flowing" through the asymptotic velocity field. The effect is very similar to the way the trajectories of objects floating on a river converge to the local flow of the water. The key feature is that the asymptotic velocity field (i.e., the flow pattern of the river) can be changed on command by simply reprogramming the motion of the plate.

The manipulator works because for any small-amplitude periodic plate motion, point parts (or rigid parts in three-point contact with the plate) move as if they are immersed in a configuration-dependent velocity field. Specifically, there is a unique mapping from every small-amplitude periodic plate motion to a corresponding velocity field, which we call an asymptotic velocity field. To a very good approximation, parts can be modeled as "flowing" through the asymptotic velocity field. The effect is very similar to the way the trajectories of objects floating on a river converge to the local flow of the water. The key feature is that the asymptotic velocity field (i.e., the flow pattern of the river) can be changed on command by simply reprogramming the motion of the plate.

We have built several manipulators called PPODs (Programmable Part-feeding Oscillatory Devices). A 6-dof PPOD consists of six linear actuators attached to a rigid plate via six linkages. Each linkage contains a compliant flexure that serves as a joint and allows the plate to move with six degrees-of-freedom. Dual-axis accelerometers are mounted around the perimeter of the plate to measure its linear and angular accelerations. We have developed a frequency-based iterative learning controller that drives the plate's linear and angular accelerations to desired small-amplitude periodic trajectories. With this controller, we can program the PPOD to move such that an appropriate asymptotic velocity field is generated to accomplish a desired manipulation task.

We have built several manipulators called PPODs (Programmable Part-feeding Oscillatory Devices). A 6-dof PPOD consists of six linear actuators attached to a rigid plate via six linkages. Each linkage contains a compliant flexure that serves as a joint and allows the plate to move with six degrees-of-freedom. Dual-axis accelerometers are mounted around the perimeter of the plate to measure its linear and angular accelerations. We have developed a frequency-based iterative learning controller that drives the plate's linear and angular accelerations to desired small-amplitude periodic trajectories. With this controller, we can program the PPOD to move such that an appropriate asymptotic velocity field is generated to accomplish a desired manipulation task.

The plate's ability to move with all six degrees-of-freedom allows for significant control over the effective gravitational force (and therefore the frictional force) that a part experiences as a function of its configuration on the plate. Previously studied systems based on vibratory plates have been limited in the types of fields they can generate because the plate's motion has been restricted in some manner. For example, a plate that can only vibrate in the horizontal plane cannot create fields with attractors (e.g., stable fixed points, which correspond to equilibrium configurations for the part). Because PPODs can move with all six degrees-of-freedom, they can generate a large class of fields including ones with stable attractors. This means that a PPOD can be used to sensorlessly position and orient parts. Other programmable manipulation systems with this capability often utilize an array of many small actuators on the plate surface to generate a vector field. By contrast, the PPOD architecture is much simpler (only six actuators) and the vector fields it generates are not spatially discretized like array-based systems.

Media coverage

Assembly Magazine article on part manipulation with a PPOD. December 19, 2007.

Funding

This material is based upon work supported by the National Science Foundation under Grant No. 0700537. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.

Related Publications

The effect of anisotropic friction on vibratory velocity fields, Robotics and Automation (ICRA), 2012 IEEE International Conference on, IEEE, pp. 2584-2591, 2012 Google Scholar

Manipulation with Vibratory Velocity Fields on a Tilted Plate, IEEE Conference on Automation Science and Engineering, 2012 Google Scholar

Sliding manipulation of rigid bodies on a controlled 6-DoF plate, Proceedings of Robotics: Science and Systems, 2011 Google Scholar

Toward the set of frictional velocity fields generable by 6-degree-of-freedom oscillatory motion of a rigid plate, Robotics and Automation (ICRA), 2010 IEEE International Conference on, IEEE, pp. 540-547, 2010 Google Scholar

Friction-Induced Velocity Fields for Point Parts Sliding on a Rigid Oscillated Plate, The International Journal of Robotics Research, vol. 28, pp. 1020-1039, 2009 DOI Google Scholar

Friction-Induced Lines of Attraction and Repulsion for Parts Sliding on an Oscillated Plate, Automation Science and Engineering, IEEE Transactions on, vol. 6, pp. 685 -699, oct./ 2009 DOI Google Scholar

Vibration-Induced Frictional Force Fields on a Rigid Plate, Robotics and Automation, 2007 IEEE International Conference on, pp. 660 -667, april/ 2007 DOI Google Scholar

Back to top